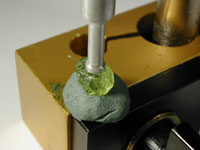

The first step is to prepare the dop stick for wax. Select a dop that will be slightly smaller than the completed stone. Clean the dop thoroughly, then apply a drop or two of "wax solution" to ensure good adhesion. For the wax solution, I use an empty medicine bottle (with eye-dropper) filled with alcohol and containing dissolved chunks of spare / excess dop wax.

Let the solution dry completely - it should leave a faint brown patina on the dop stick.