Tom's Transfer

What is this all about ?

This page describes a technique for quickly and accurately setting the appropriate

cheater (index splitter) angle after transferring a stone. It can also be used

to replace a dop in the machine under other circumstances - for example to touch

up the star facets after completing the table. The technique does not require

any further cutting or polishing of facets, and it can be used at any time to

restore the desired cheater angle (provided that there is a polished girdle

facet). The entire procedure takes approximately 5 minutes, and is very accurate.

Why is this necessary ?

(If you already understand cheater adjustment after transfer, you can skip

to the next section.)

Transferring a half-completed stone to a new dop involves two factors which

can cause misalignment of the pavillion and crown facets. The first of these

is simply removing the dop from the machine (which may be necessary or helpful

even when not doing a transfer). Despite various keying schemes, the second

dop is invariably somewhat rotated with respect to the first, requiring some

cheat to bring things into alignment. The second factor is imperfect transfer,

possibly due to misalignment or keying problems in the transfer jig, slight

shifting of the stone, etc.

To counter these difficulties, faceters have developed a variety of schemes

to determine the correct cheat angle. One common strategy is to cut a row of

facets after transfer. Incorrect cheat angle shows up as a slight spiral cut,

producing an offset between the last and first facets cut. The faceter applies

some cheat in the appropriate direction , cuts another row of facets, and checks

again. A few iterations should produce an even row of facets and hence the correct

cheat angle. Rob Kulakofsky wrote an excellent description of this method (AFMS

faceters list archive).

Unfortunately, there are several problems with this technique. First, it is

very slow, since accuracy depends on adjacent facets being cut to exactly the

same depth. Any overcut of a facet halfway through a row forces the faceter

to compensate or start over with that row. Achieving maximum yield from expensive

rough is also inconsistent with cutting multiple test rows of facets. In addition,

many gemstone designs do not have continuous facet rows. Check the first crown

cut. If it does not produce a continuous girdle line, you will have to cut all

the way around the stone at the largest angle. This may be problematic for some

gem rough. Finally, this technique does not help with the problem of replacing

the dop in the machine at times other than transfer.

Tom's Transfer

I got very frustrated with the cut and check technique for getting the right

cheat after transfer, and therefore started looking at alternatives. My experience

in astronomical instrument design started me thinking about possibilities for

optical alignment. The method outlined below is based on a standard technique

known as retroreflection, in which a beam of light returns exactly to its source

after reflection off the surface being aligned.

|

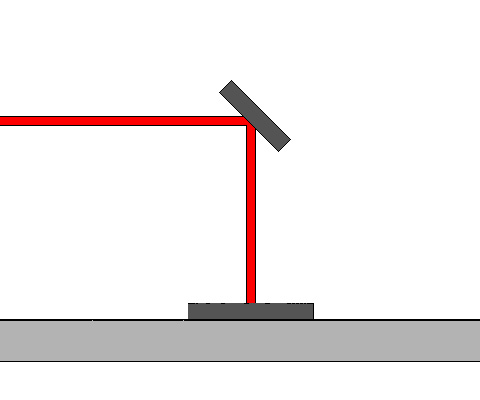

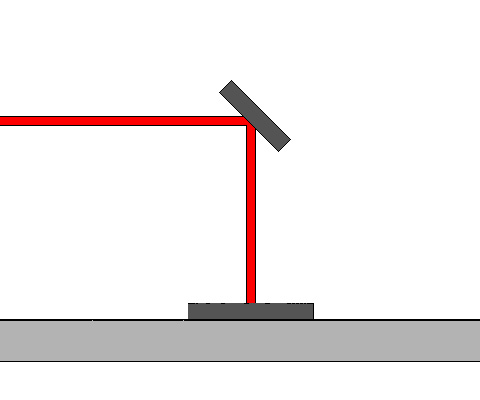

The figure at left outlines the basic principle. A mirror placed on a

flat reference lap bounces laser light exactly back along its incoming

path. A second mirror held at approximately 45 degrees allows the incoming

and outgoing beams to be horizontal, a configuration better suited to

long optical path lengths in typical rooms (no cathedral ceilings in my

little workshop!). Also, adjusting this 45 degree mirror is much easier

than positioning the laser for perfect retroreflection.

Note that if the light goes exactly back to the laser, the optical path

between the two mirrors is by definition exactly perpendicular to the

lower mirror, and hence to the reference lap.

|

|

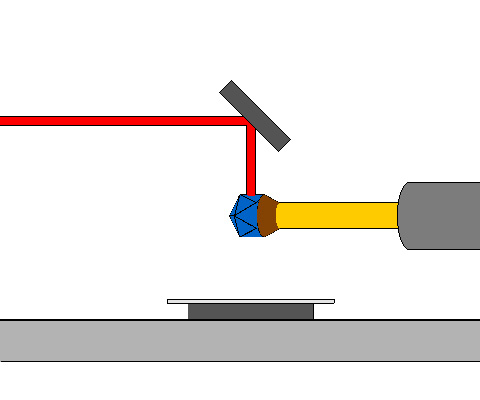

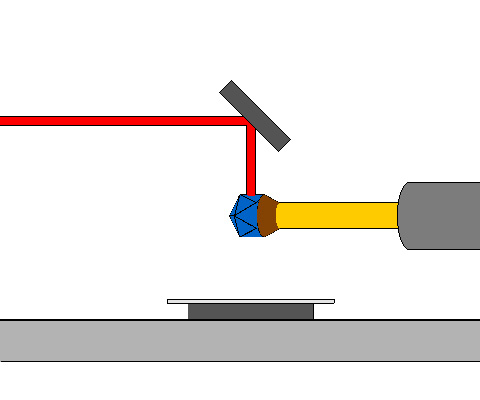

The next step is to tie the orientation of the gemstone into this reference.

Setting the protractor to 90 degrees and selecting an index exactly opposite

a girdle facet should make that facet also parallel to the reference lap

and upward-facing. If the gem is properly aligned, the laser should retroreflect

off the girdle facet just as it did off the lap mirror (I usually cover

the lap mirror with paper to minimize confusing reflections). Adjusting

the index splitter (and protractor) for perfect retroreflection gives

the proper cheater angle. Voilà.

|

|

What you will need.

To do this yourself, you will need the following items:

A Laser Pointer

2 Small (25-50 mm, 1-2 inch) mirrors

A jig to hold the 45 degree mirror

Laser Pointer. I use a cheap laser pointer purchased at a discount house

for less than $20. The only requirement here is that the laser stay on continuously.

My pointer has a recessed momentary-on switch, which I hold down with a breath

mint and an elastic band.

Mirrors. Almost any mirror will do. The one lying on the lap should

provide an accurate reference. This means it should either be a first surface

mirror face down, or at least a double surface mirror that is very parallel.

You might be able to judge how parallel such a mirror is by rotating it 90,

180, and 270 degrees then checking whether the spot stays fixed after retroreflection.

Edmund Scientific has suitable inexpensive mirrors.

Jig to hold 45 degree mirror. I began with a hobbyist's "third

hand" - the gadget with alligator clips and wing nuts. This was difficult

to control, so I rigged together a mirror holder with screw adjustment. For

the ultimate in ease, try to scrounge surplus hardware from an optical bench.

Like this.

Detailed Instructions

1. Place the lap mirror on a clean reference lap. I use a mirror approximately

30 mm in diameter laid on my master lap. Place the mirror where you usually

polish. The mirror will rest on top of any small hills on the lap, averaging

the slope over the area it covers.

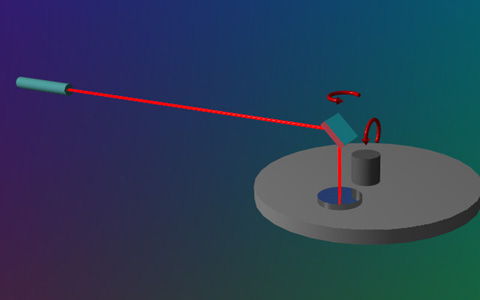

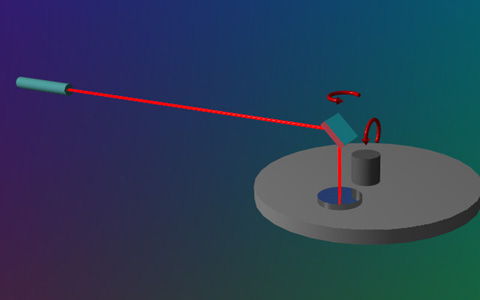

2. Setup up 45 degree mirror and laser. I place the mirror holding jig

directly on the lap, so that the 45 degree mirror is directly above the lap

mirror and pointing across the room to the table where the laser sits.

|

3. Align laser to lap mirror. See figure at right. Turn on the

laser and adjust it so that the beam strikes the 45 degree mirror. If

you have trouble getting it to line up and stay put, try embedding the

laser in some plasticene (Play-Do). Adjust the 45 degree mirror so that

the spot of light returns to the laser. This does not have to be exact

, as long as you send the laser back to the same spot in step 4.(see here

for a discussion about this).

|

|

|

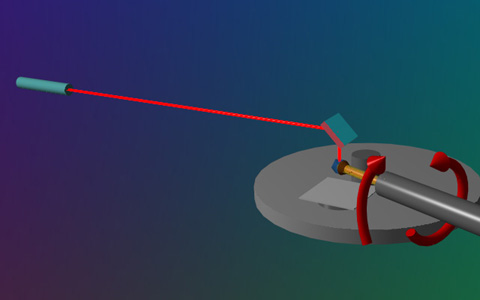

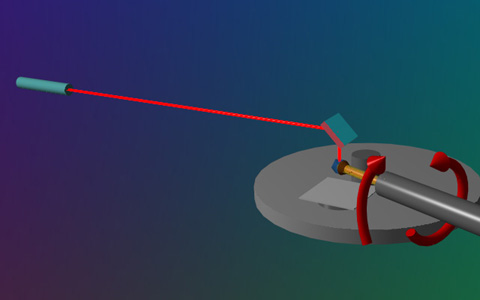

4. Align the gem to the lap. See figure at right. First, cover

the lap mirror with a tissue to prevent distracting reflections. Then

dial in 90 degrees on the dop arm and set the index so that a polished

girdle facet faces upward (do this from the design, not by eyeball! For

instance, if there is a girdle facet at 24 on a 96 tooth gear, set the

index to 72). Make sure that the downward-travelling laser beam strikes

the girdle facet. A small white index card can be a great help here. Reflection

off the facet then the 45 degree mirror sends the light back toward the

laser pointer. You might get addtional confusing reflections off other

facets. Inking unused facets helps here. Adjust the protractor and cheater

angles until the spot returns exactly to the laser (or the location it

was before). That's it. Do some reality checks (step 5) then start cutting!

|

|

5. Do some reality checks. You should check the laser-lap mirror alignment

afterward. Just move the stone out of the laser beam and remove the tissue covering

the lap mirror. The spot should stay put. There are some additional useful checks.

For example, you should check the spot location using different facets. If the

spot moves around slightly, repeat step 4 using the facet which represents the

approximate middle position. How much variation is acceptable? Compare the amount

of cheat you have to apply to bring the spots to the same point. If this is

small compared to the amount of cheat you apply during normal faceting, you

should be all right. Read some additional comments about accuracy here.

Some Remarks about Accuracy

This optical alignment technique is very accurate. We can estimate the cheater

angle error using the laser spot uncertainty and some simple geometry. For example,

with my setup, I can usually retro-reflect the laser to within 1 mm or so of

its original location. With a total path length from the gemstone to the laser

head of about 2.5 meters, this corresponds to an angular accuracy of 1 part

in 5000 (note that when you rotate a mirror - or a gem facet - by one degree,

the reflected light is rotated by 2 degrees). One part in 5000 corresponds to

approximately 0.01 degrees or 0.7 minutes of arc. For a 96 index gear, it is

about 1/300th of an index setting.

Is this accurate enough? The simple answer is yes, for at least two simple

reasons. First, you will likely find as I did that aligning this way produces

no discernible error with the traditional cut-and-check technique. Second, you

will notice that cheater adjustments that you would normally consider minute

during faceting produce significant shifts of the laser spot.

Improving Accuracy

A longer path length would allow greater accuracy, although it becomes harder

and harder to judge the center of the spot of light, particularly that produced

by an inexpensive laser pointer. Yes, a HeNe gas laser with less beam divergence

would improve things.

Imperfect retroreflection - that is returning the laser spot to a point slightly

displaced from the laser head - does introduce some inaccuracy. The figure below

explains why.

A Word of Caution

This technique should simplify the procedure of finding the correct cheater

setting, but it is subject to error. Obviously, referencing to the polished

girdle facets in this way presumes that you have an accurate girdle. Bumping

or moving the lap, mirrors, or laser during the measurement can cause problems

as well. As a matter of practice, I usually cut a test row of facets to confirm

accuracy, but I rarely have to cut more than one row!